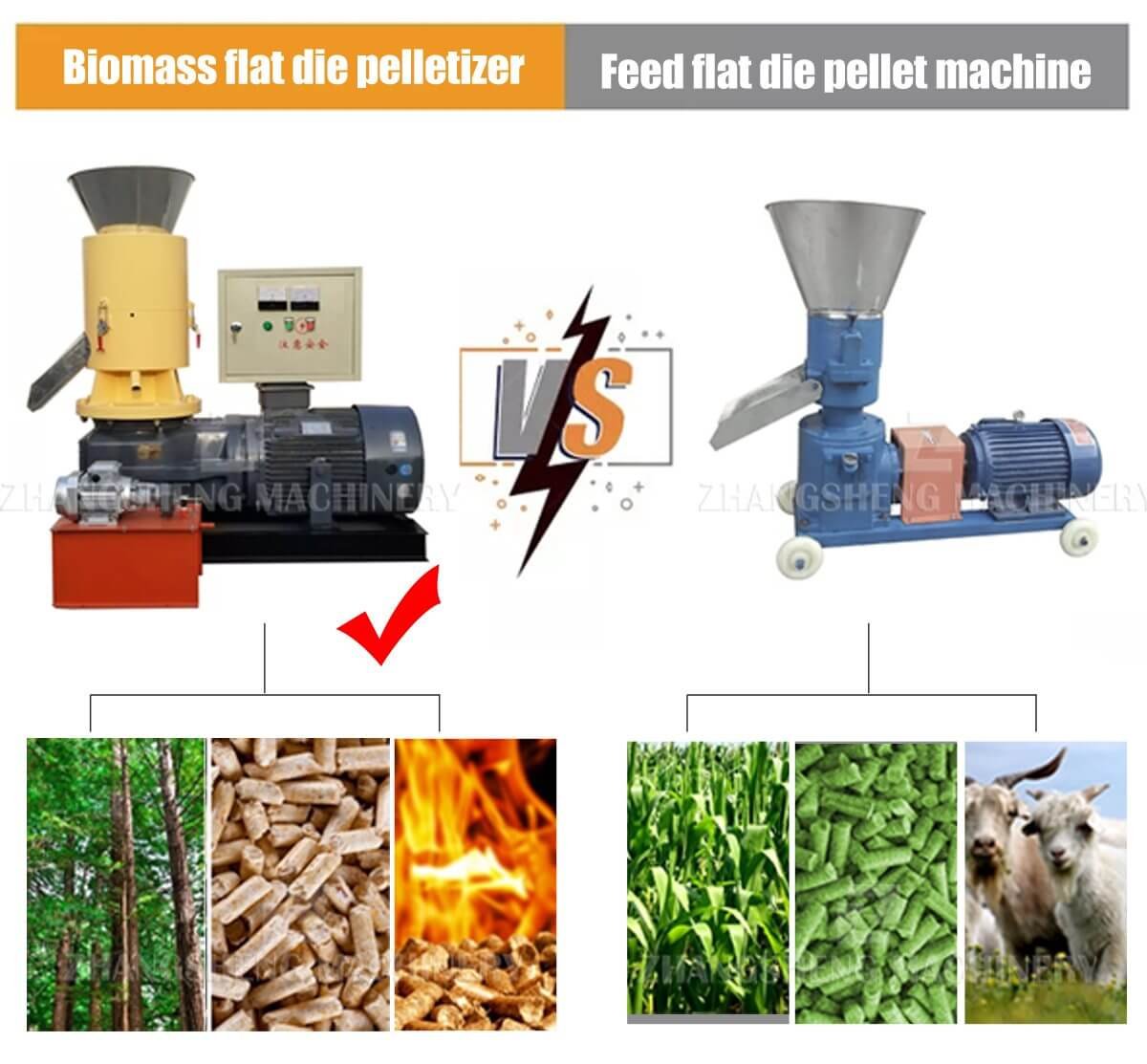

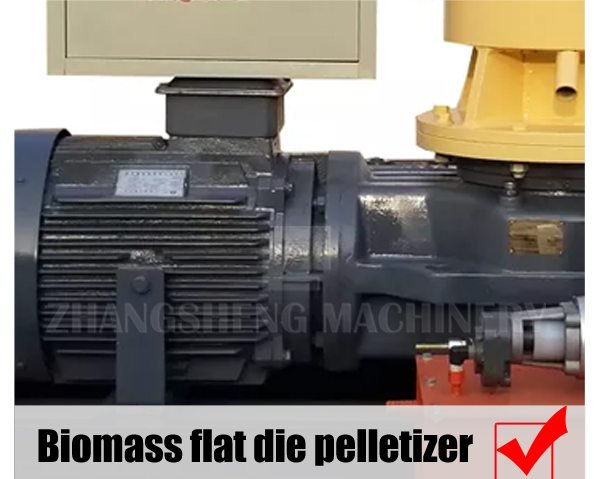

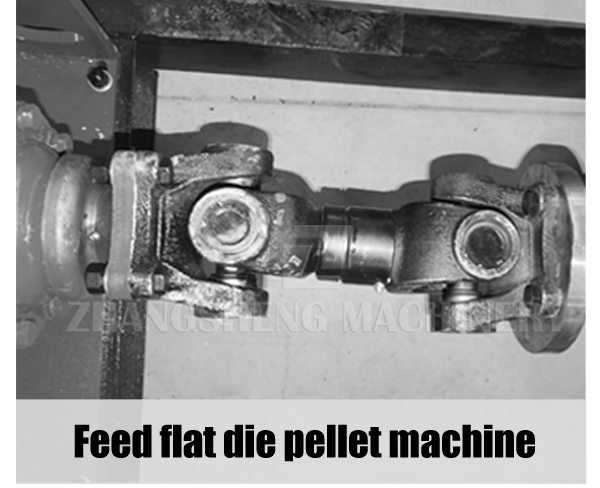

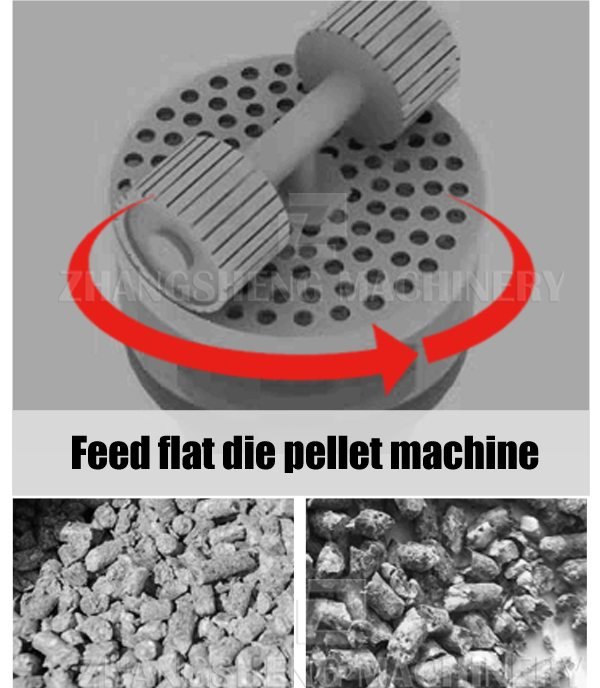

Small flat die granulator is one of our main products, also known as flat die granulator. The small machine is easy to operate and suitable for home use. After years of technical improvement, it is very suitable for making wood chips for burning, pellets, high output, and energy efficiency. Low consumption and easy operation.

- Home

- Wood Recycling

-

- Wood Chipper

- Application

- Video

-

Case

-

Wood chipper

12 inch Wood chipper machine in Australia 6 inch Wood Chipper in Georgia Wood Chipper Model ZS1500 In Australia Wood Chipper Model ZS600 In Thailand Wood Chipper Model ZS600 In Canada Wood Chipper Model Z1000 in United Arab Emirates ZS-1000 Model Wood Chipper In Malaysia ZS-1000 Model Wood Chipper In Argentina 12 inch brush chipper machine in Mexico 12 inch wood chipper machine in Russia 16 inch Wood Chipper in Vietnam Wood chipper Z1000 delivered to domestic customers Wood Chipper Model ZS600 In Spain

- Horizontal Grinder

-

Wood pellets production line

Wood pellets production line in Indonesia Biomass pellet production line in Thailand Wood pellets production line in Thailand Biomass pellet production line in Indonesia Wood pellets production line in Canada Wood pellets production line in Malaysia Wood pellets production line in Turkey Biomass pellet machine in Vietnam Biomass pellet line in Chile Wood Pellet production in UK wood pelletizer equipment in china Wood pellets production line in Australia

- Wood flour machine

- shredders

- Wood crusher

- Tub Grinder

- Hammer Mill

- Water Drop Pulverizer

- Disc chipper

- Flat Die Pellet Machine

-

Wood chipper

- Service

- About Us

- Contact