Rich experience

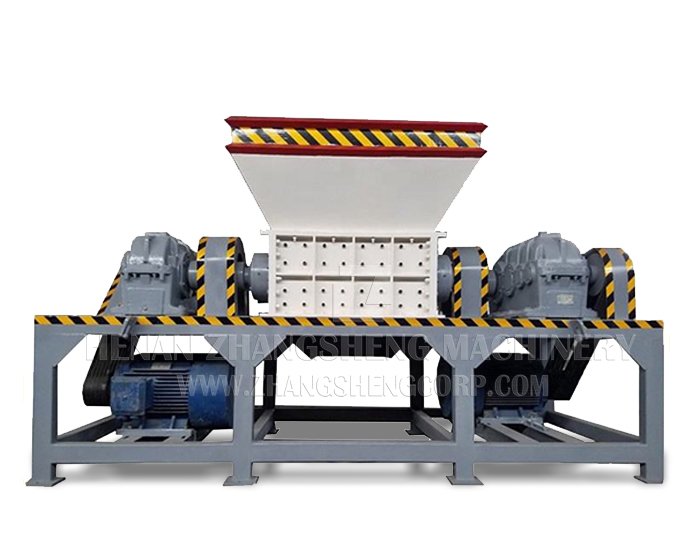

Since 2002, we have been producing wood crusher machine, horizontal grinders and other wood recovery equipment. Whether you need to make pellets, charcoal or organic fertilizer, we have very professional solutions and manufacturing experience, we are full of confidence to be your reliable business partner.